{{ galleryProps.activeIndex + 1 }}/10

Description

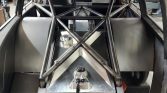

Experience the ultimate in luxury and uniqueness with this one-of-a-kind 1951 Nash Rambler. This high-end, fully custom-built car is a testament to the care and precision that went into every aspect of its construction. No expense was spared in its creation, and every part was hand-built or one-off designed. Believe us when we say that the details of this car are too numerous to list here. However, we are more than happy to provide a full rundown of…

Experience the ultimate in luxury and uniqueness with this one-of-a-kind 1951 Nash Rambler. This high-end, fully custom-built car is a testament to the care and precision that went into every aspect of its construction. No expense was spared in its creation, and every part was hand-built or one-off designed. Believe us when we say that the details of this car are too numerous to list here. However, we are more than happy to provide a full rundown of the build upon request. If you’re looking for a truly unique ride that exudes luxury, this is the car for you. Don’t wait – send us a direct message today to make it yours.

Before you decide to buy a car, read its history for free.

Type

•

Classic Cars / Classic Trucks

$100,000

Mileage:

1,234 miles

Model:

Rambler

State:

UT

City:

SAINT GEORGE

Type:

Classic Cars / Classic Trucks

Year:

1952

Offer ID #191138

Send message

Related listings

Copyright © 20243. All rights reserved.

By using this service, you accept the terms of our Visitor Agreement | Privacy Statement

Powered by Updog Web